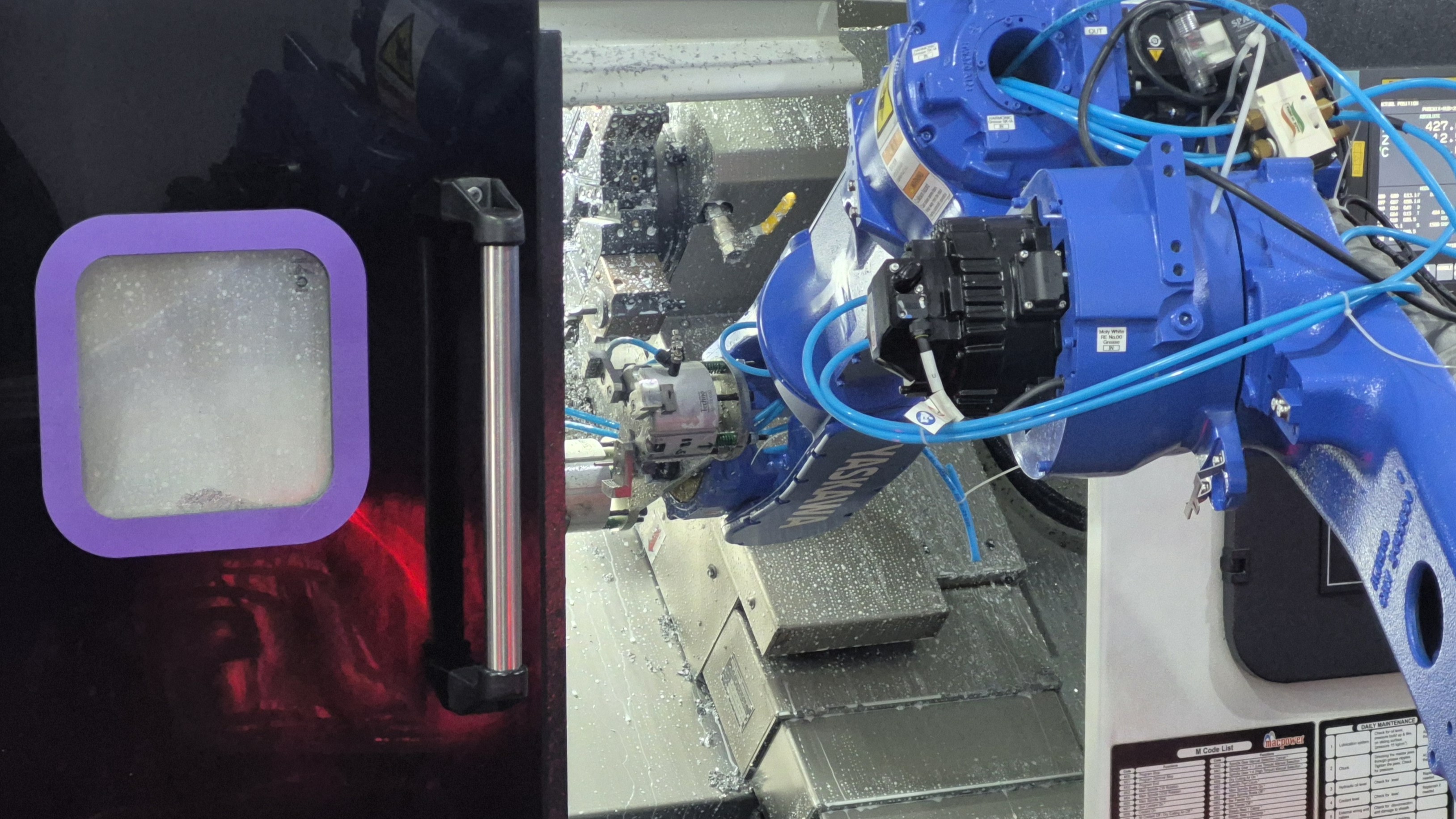

Automated Clutch Manufacturing Cell

High-precision robotic integration for automated CNC machine tending, optimizing the manufacturing cycle of industrial clutch chucks with 24/7 operational reliability.

Client

Autologic Industries

Year

2025

Transitioning from Manual Labor to High-Precision Robotics

In many traditional manufacturing environments, the production of clutch chucks has long relied on the physical endurance of a skilled workforce. For years, this process required operators to manually lift and position heavy, raw castings into CNC machines throughout the day. While this approach was the industry standard, it inevitably introduced human fatigue into the production cycle, leading to natural inconsistencies in timing and potential safety risks within the high-pressure machining zone. The core challenge was to liberate workers from these repetitive, strenuous tasks while ensuring the manufacturing line could maintain a steady, unbreakable pace.

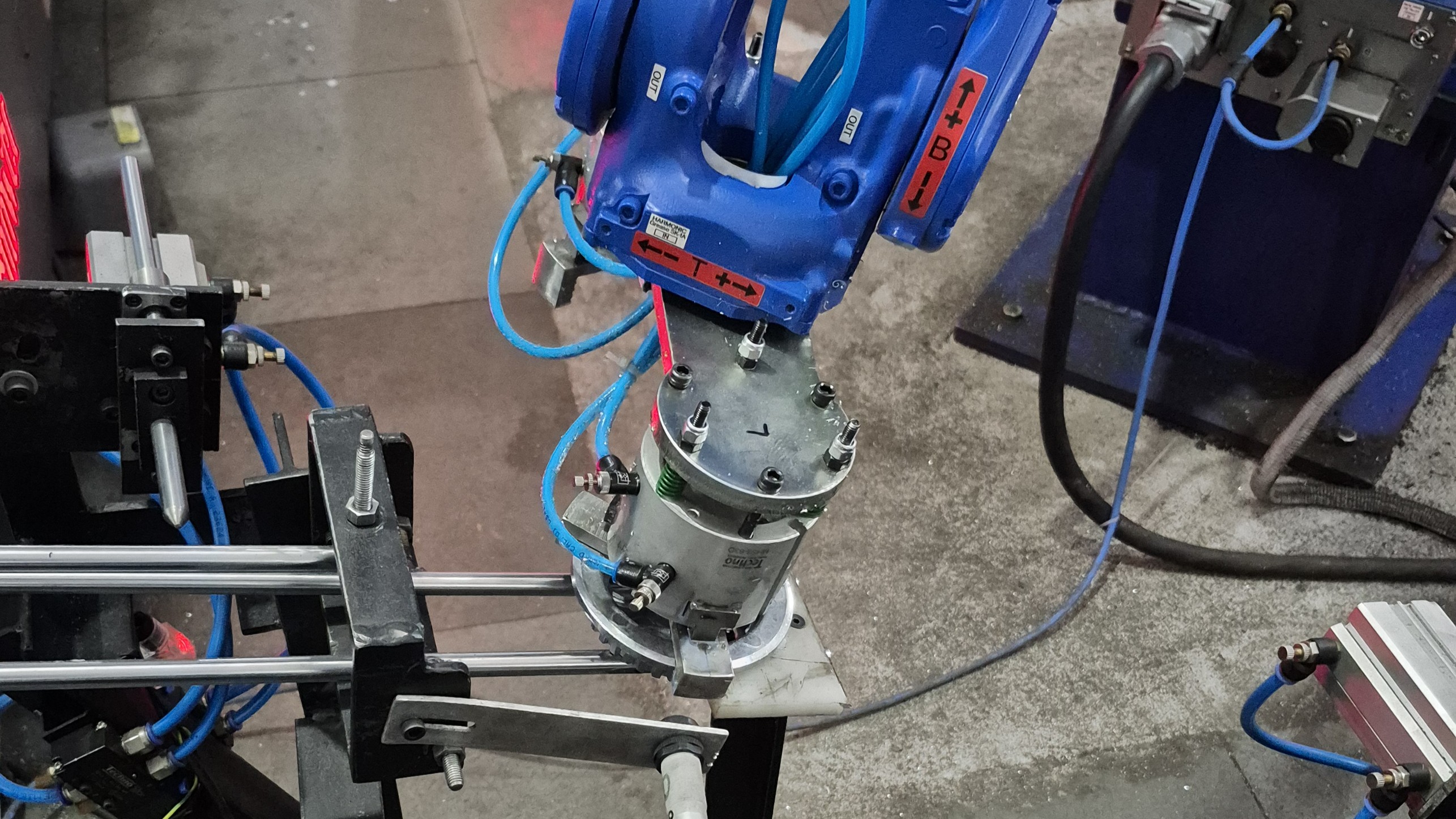

To address this, we implemented a fully autonomous robotic tending cell that reimagines the entire material flow. By integrating a high-performance industrial robot, the system now manages the process from start to finish, picking each raw casted part one-by-one and placing it into the respective CNC machine queue. This robotic intervention ensures that every machine is fed with absolute precision, creating a synchronized manufacturing environment. By replacing manual handling with robotic intelligence, the facility has moved from a labor-dependent workflow to a relentless, automated engine of production that operates with total reliability and zero downtime.

Project Gallery

Ready to innovate your production line?

We combine certified expertise with end-to-end in-house capabilities to deliver robust, intelligent automation solutions.

Contact us